Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

ZX Series

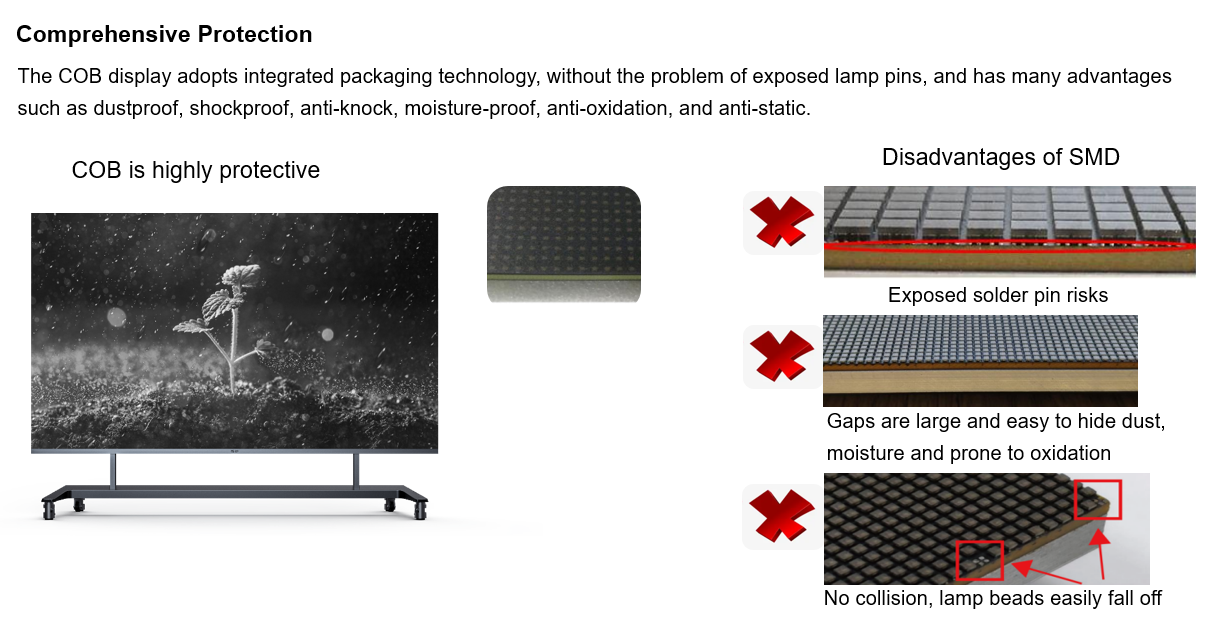

Wire bonding is a crucial technology in the manufacturing of COB LED displays. It offers numerous benefits, including precise electrical connections, flexibility in chip design, efficient heat dissipation, and high reliability. As a result, wire bonding enables the production of high-quality, compact, and energy-efficient LED displays that can be utilized in a wide range of applications, such as government, hospital, airport, subway, exhibition hall, chain store.

Wire bonding is a commonly used technique in the electronics industry for connecting integrated circuits to their packages or substrates. In the case of a COB (Chip-on-Board) LED display, wire bonding is used to connect the LED chips to the substrate. COB LED displays are characterized by multiple LED chips placed directly on a circuit board, without the use of individual LED packages. This creates a compact and efficient lighting solution. Wire bonding is used to establish electrical connections between the LED chips and the board, ensuring proper functioning of the display.

The wire bonding process involves attaching tiny wires, typically made of gold or aluminum, from the contact points on the LED chips to the corresponding pads on the substrate. This is done using specialized wire bonding machines, which utilize ultrasonic or thermosonic bonding techniques to form reliable and secure connections. Some benefits of wire bonding in COB LED displays include improved thermal management, enhanced electrical conductivity, and compact design. Additionally, wire bonding enables high-resolution displays with excellent color consistency and brightness.

- Wire bonding COB packaging technology

- Support quick installation, adopt die-casting aluminum cabinet, super high flatness

- Support front maintenance of modules, receiving cards, power supplies and other accessories

- Super high contrast, support brightness and chromaticity correction, stable and reliable image quality

- 16: 9 golden ratio, support 2K/4K display, perfect point-to-point display effect

Applications

- Exhibition Display: COB LED displays are commonly used in exhibition displays to showcase products, promotions, or information. These displays offer high brightness and contrast, allowing for clear and engaging visual presentations

- Emergency Response Center: In an emergency response center, COB LED displays can be used to efficiently relay critical information to responders and coordinate rescue efforts. These displays can display real-time data, maps, videos, and other crucial information

- Business Center: In a business center, COB LED displays can be used for advertising, presentations, and information dissemination. They can display advertisements, announcements, conference schedules, or company information, enhancing communication and engagement with clients and employees

- Security Monitoring: COB LED displays are vital in security monitoring centers as they provide real-time surveillance footage, alarm notifications, and access control information. The high-resolution display ensures clear and detailed visuals, enabling security personnel to monitor and respond effectively

- Education: COB LED displays find applications in classrooms, auditoriums, and training centers. They can be used to display lectures, presentations, interactive content, and educational materials. These displays enhance visual learning experiences, making education more interactive and engaging

- Medical Care: In a medical care setting, COB LED displays can be used to display patient information, medical imaging, surgery progress, and other critical data. These displays offer high color accuracy and precision, ensuring accurate interpretation of medical visuals and facilitating better patient care

|

Model |

TC-ZX0.9 |

TC-ZX1.2 |

|

Pixel Pitch (mm) |

0.95 |

1.26 |

|

Module Size |

304*342mm |

|

|

Module Resolution (pixel) |

320*360 |

240*270 |

|

Bottom Case Material |

Aluminum |

|

|

Die Casting Cabinet Size |

608*342*48mm |

|

|

Display Unit Size |

640*480mm |

|

|

Display Unit Weight |

7KGS/Cabinet |

|

|

Display Unit Resolution |

640*360 |

480*270 |

|

Pixel per Square Meter |

1108034 |

623334 |

|

Flash Correction Storage |

support |

|

|

White Balance Brightness (nit) |

600nit |

|

|

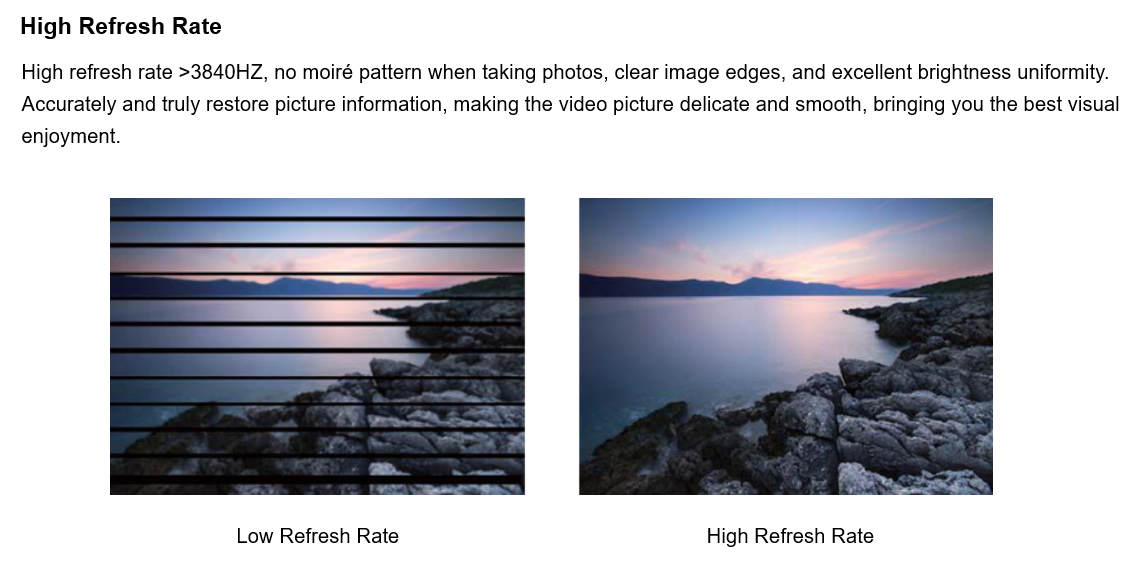

Refresh Rate (Hz) |

3840 |

|

|

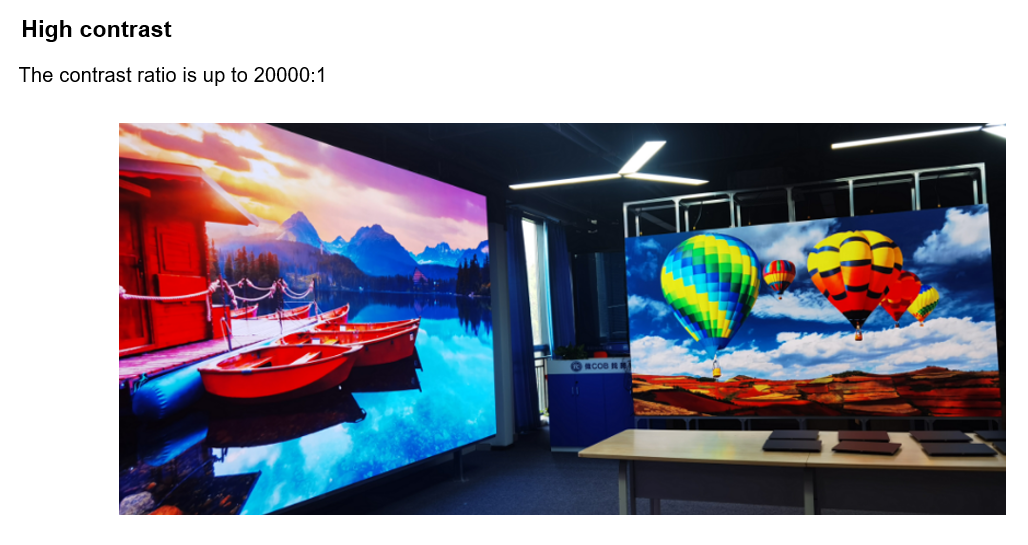

Contrast Ratio |

20000:1 |

|

|

Color Temperature (K) |

3200K-9300K Adjustable |

|

|

Viewing Angle |

170° Adjustable |

|

|

Display Unit Input Voltage |

AC 100-240V 50/60Hz |

|

|

Max. Power |

470W/m2 |

|

|

Average Power |

140W/m2 |

|

|

IP Grade |

IP65 |

|

|

Working Temperature and Humidity Range |

(-10℃ to +40℃)/10%RH to 90%RH |

|

|

Storage Temperature and Humidity Range |

(-10℃ to +60℃)/10%RH to 90%RH |

|

|

Certification |

CCC, EMC CLASS-A,CE,ROHS |

|

Project Cases